Craftspeople develop heritage.

Noardling is where Desah, Hubert and Landustrie continue together as one. With a combined history of more than 250 years, we now use our expertise and innovative strength to supply sustainable solutions in water technology.

We are Noardling: new name, familiar craftsmanship.

We are Noardling

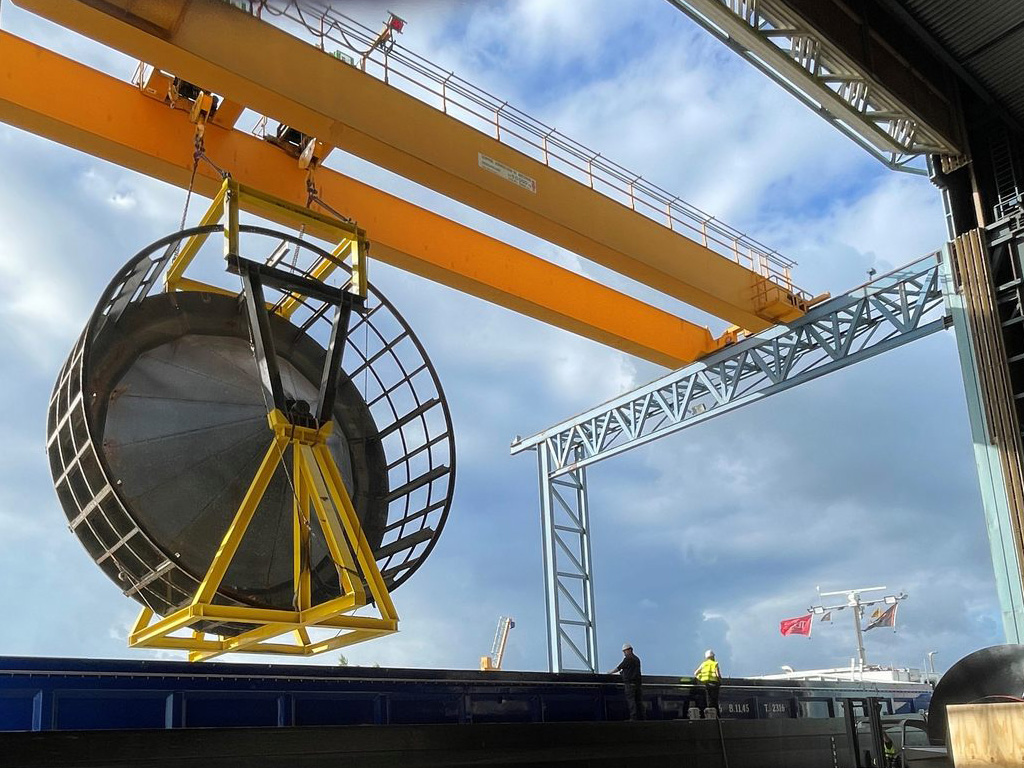

Noardling stands for Futureproof Water Technology: sustainable solutions for the entire water cycle, from water intake to wastewater treatment and from water transport to hydropower generation.

Under the name Noardling, we unite more than 250 years of experience of three strong brands: Desah, Hubert and Landustrie. Each with its own speciality, together strong in quality, innovation and craftsmanship.

We are proud of our heritage, but also focus on the future. Our technology is designed to last for generations and contribute to a circular world.

And above all: we are professionals. Committed, knowledgeable and driven to make a difference every day. Together, as one Noardling.

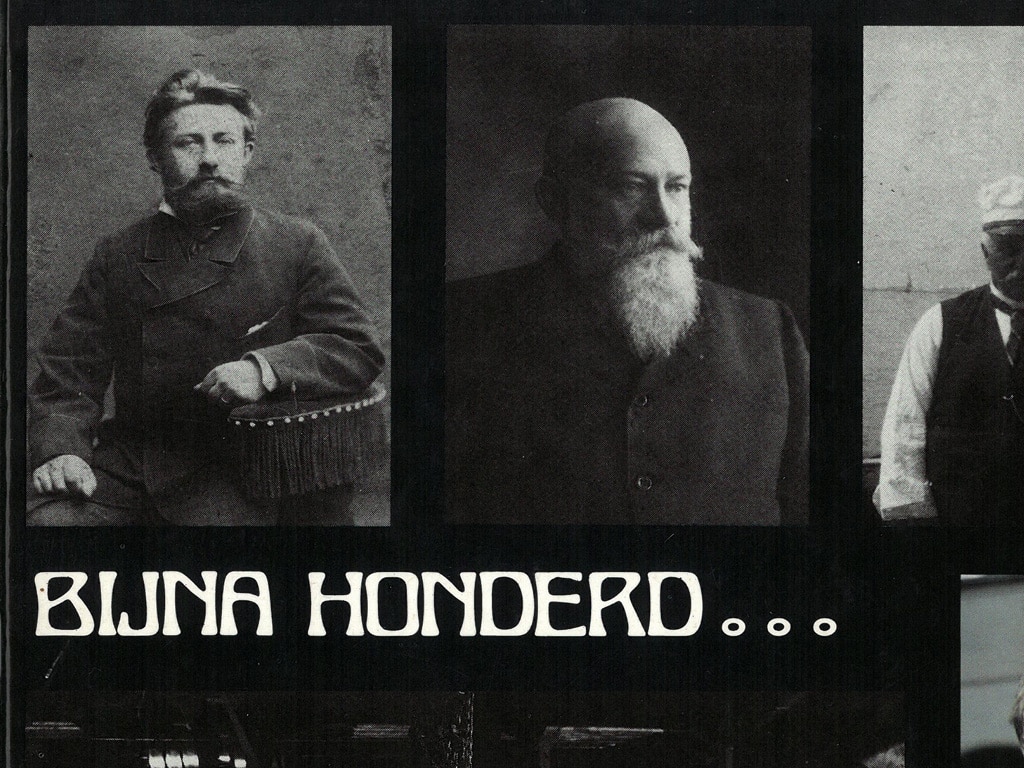

Heritage in motion

Future-proof and values-driven.

Craftsmen are at the heart of Noardling. For more than five generations, we have been working on water technology for tomorrow. Our heritage is more than history, it lives in what we do today and how we pass it on as one to the generations to come.

Craftsmen

Beautiful and memorable. We stand for who we are, what we create and what we do. With our eyes on tomorrow, we now put our shoulders to the work for today.

Our Heritage

We put our knowledge and skills at the service of our heritage: our future-proof water technology, which future generations can build on.

The Whole

As a whole, we transcend the sum of our parts and enhance each other's talents. Through social connection, togetherness, and a spirit of helpfulness, we stand as one!

What we do makes a difference

Follow our story

Wondering how we are building water technology for tomorrow's world?

Sign up for the Noardling newsletter to receive inspiring stories and innovations from us and our brands Desah, Hubert and Landustrie.

"*"indicates required fields